K3 Series GCRT

Rigging Point

It adopts frequency conversion technology, constant speed drive, multiple units for grouping, and efficient synchronization. It is suitable for hotel banquet halls, multifunctional conference centers, etc. It can also be programmed by PC to control the different speeds of each crane to create a changing stage effect. Equipped with independent self-developed wireless administrator controller, no matter remote operation or on-site control, it can provide more secure protection.

Major Function:

• Built-in frequency conversion circuit, which can be variable speed or constant speed to ensure consistent loading and unloading under heavy load and light load.

• Built-in control system, remote control can be implemented through RS485 port.

• Low voltage control with low voltage current dry contact control

• Upper and lower limit physical and electronic limit.

• Double brake system, heavy-duty DC electromagnetic brake, safe and durable; electronic brake, compliant brake

• Gears (transmissions), precise helical helical gearbox, full load noise as low as 68 dB

• Overload protection, electronic current limit overload protection design, limit is not more than 20% of the rated weight, prevent extreme overload, and effectively avoid the danger caused by overload.

• The incremental encoder provides timely feedback to the control system, forming a closed-loop detection, and providing data for creating changing stage effects. Can be freely set to form positioning.

- GCRT 2512

- GCRT 5012

Parameter

-

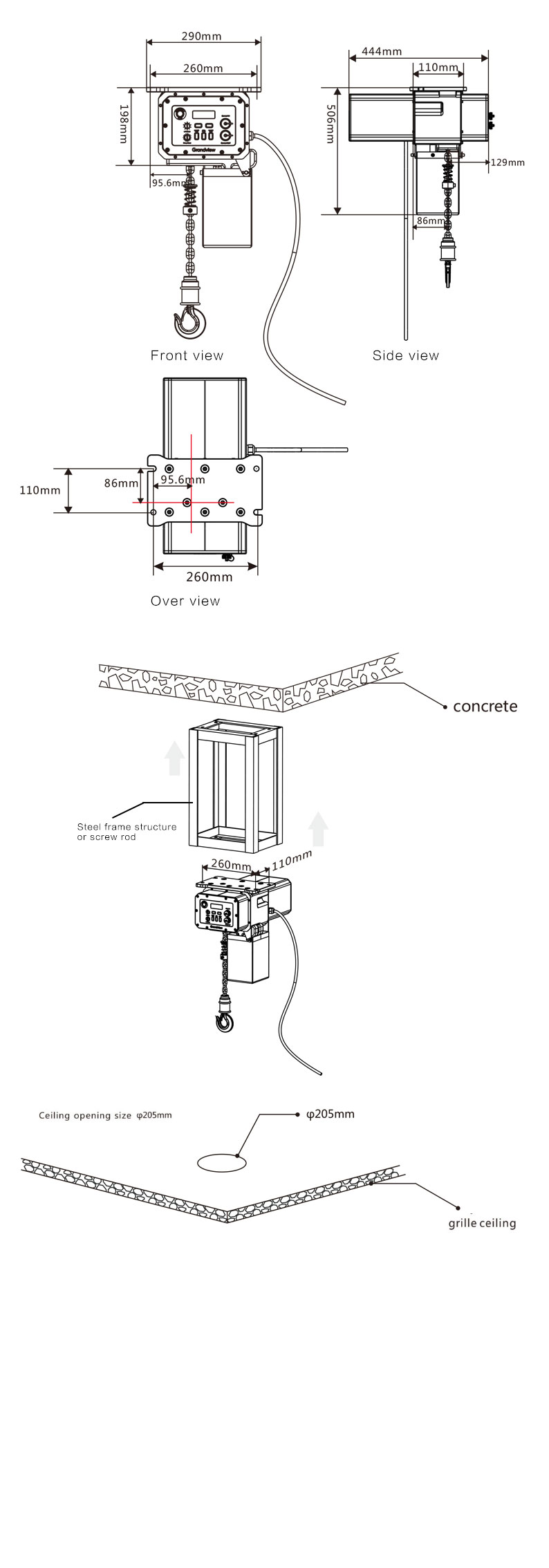

Product Dimensions

(D×W×H)mm444×290×506

-

Net Weight

(kg)36.8

-

Max Load

(kg)250

-

Power

(w)300

-

Max Travel

(mm)12000

-

Precision

mm<1mm

-

Noice

(dB)≤68dB

-

Voltage

220V

-

jib attachment

mm260x110

-

Ceiling Opening Dimensions

(D×W×H)mmφ175

-

Dry Contact

Y/N√

-

485 Control

Y/N√

GCRT-5012 Instruction Manual (PDF)

GCRT-5012 Instruction Manual (PDF)